Time to read: 6 min

The Power of 3D Printing: Unlocking Complex Lattice Structures

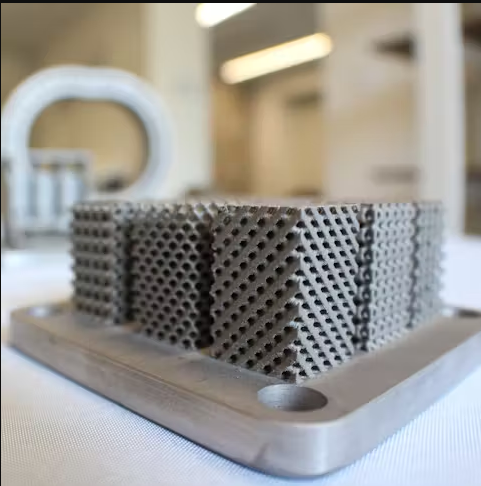

One of the most remarkable capabilities of 3D printing is its ability to create parts with intricate internal lattice structures that are unattainable through traditional manufacturing methods. This innovation not only enhances design possibilities but also opens up new avenues for optimizing material usage and part performance.Understanding Lattice Structures in 3D Printing

A lattice structure in 3D printing is essentially a 3-dimensional assembly of connected nodes, which can be either repeating or non-repeating. In its simplest form, multiple lattice nodes are connected by beams to form regular shapes like cubes or tetrahedrons, often referred to as cells. The shape and density of these cells determine how the part will behave under load. By strategically placing material only where it is structurally necessary, 3D printed lattice structures achieve significant weight reduction while maintaining strength.The Advantages of Lattice Structures in 3D Printing

Lattice structures offer several key benefits that make them highly valuable across various industries:Reduced Part Weight: By using material only where needed, lattice structures significantly reduce the overall weight of parts. This is particularly advantageous in aerospace and automotive applications, where lighter parts translate directly to improved fuel efficiency.

Enhanced Strength-to-Weight Ratio: When designed according to Design for Additive Manufacturing (DFAM) principles, lattice structures can achieve unparalleled strength-to-weight ratios, making them ideal for applications where minimizing mass is critical.

Improved Shock Absorption: The cellular configuration of lattice structures allows them to flex and dissipate energy efficiently, making them highly effective at absorbing impacts and even stopping bullets in some cases.

Increased Surface Area: Lattice structures provide more surface area without increasing the overall footprint of the part. This is beneficial for applications like heat transfer and chemical reactions, where maximizing surface area is crucial.

Osseointegration: In medical applications, lattice structures can be designed to promote bone growth, creating stronger bonds between implants and the patient's natural bone structure.

Generating Lattice Structures

Creating lattice structures involves specialized techniques due to their complexity. Typically, parts are initially designed in CAD software as solid objects. After incorporating DFAM principles, the model is imported into specialized software like Netfabb or nTopology to generate the lattice structure.Another approach is generative design, where an algorithm generates multiple solutions based on defined connection points, mass limitations, and expected loads. The optimal lattice cell structure and density are then selected from these solutions or further refined through iteration. Key factors to consider when creating lattice structures include:Lattice Material: The lattice can be made from the same material as the part or involve multi-material designs, such as using flexible materials for the lattice and more resilient materials for the outer shell.

Lattice Structure: Advanced methods vary the density and shape of cells to provide more strength where needed and reduce material in less-stressed areas.

Cell Orientation: Proper orientation of cells during printing can minimize the need for support structures and simplify the printing process.